English

English

The new challenge of the Industry 4.0 and Smart Cities sector: Certified and quality data

The press and media at the European level are already echoing the recent approval of the European Green Deal, which sets the challenge of being neutral in greenhouse emissions by 2050. Smart Cities have already begun this transition, working on identifying their main sources of pollution for the development of sustainability strategies.

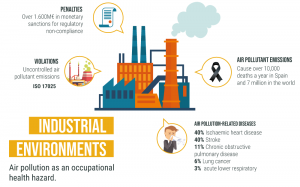

Environmental control also affects Industry 4.0 at different levels, the emission of gases into the ozone layer that affects the population, and the generation of harmful components of air in the working area, which directly interfere with workers’ health.

On a large scale, relevant measures are being taken to control and reduce air emissions thanks to regulations such as EN 13725 on odor control, but in the working environment, more thorough monitoring with monitoring systems is needed. These systems must allow for the detection of dangerous situations at an early stage in order to protect employees and justify compliance with regulations such as the Environmental and Occupational Therapy Law.

“In Industry gas emissions mean more than 7M deaths per year in the world and a dedication of 1,600M euros in sanctions” Iris Cuevas, Chemical Engineer at HOPU.

In order to control this situation, quality control campaigns of the working environment are being carried out by certification companies, through specific inspections. However, these are concrete measures to comply with current regulations. This type of industry requires a system that certifies in real-time that its workers have been in a space free of components that are harmful to health, in accordance with the health parameters established for each one. In this way, they will be able to detect harmful situations at the time and take the necessary measures to protect their workers.

First Blockchain pilot for air quality in Industry 4.0

Thanks to HOPU’s experience in developing air quality monitoring systems for Smart Cities we have a solid product for measuring greenhouse and harmful gases, suspended particles, odors, and noise, with an accuracy of over 90%.

Air quality measurements in the industry should always set an example in terms of rigor and certification as this data has a very relevant impact and serves to make critical decisions in the surrounding business fabric.

This is where HOPU proposes a technological innovation to meet this need for monitoring the health of the working environment in real-time. By using the potential of the Blockchain, HOPU is certifying and protecting the data collected by its air quality monitoring devices for use in Industry 4.0. In this way, the industry can verify real-time control of the area to satisfy the regulations regarding the working environment with certified data and justify critical decisions in the environment.

Thanks to Blockchers, a research group working to promote the use of DLT (Distributed Ledger Technologies) in European companies, HOPU is executing its first pilot deployment to validate this Blockchain certificate. With this pilot and our knowledge in the technological and environmental sector, HOPU is expanding its area of action towards the Industrial 4.0. market and improving its services for Smart Cities. This validation is being carried out in the Lisanplast plastic factory, which seeks to ensure that the work environment is suitable for pregnant and nursing women and to monitor the health of employees.

The pilot consists of continuous monitoring of data from the working environment through the Smart Spot HOPU devices, using open technologies such as FIWARE´s CEF Context Broker, to analyze this data and detect anomalies and events. For this development, HOPU is using the B Besu Alastria network, which is regulated and compatible with the European network. In this way, compliance with regulations in the workspace is verified, a calculation of total emissions is provided and all this in an accessible and intuitive interface to access the data in real-time and in history.

“According to Lisanplast’s prevention regulations, workers were only required to wear masks and earplugs at specific locations in the factory. When we installed the HOPU sensors and saw the measurements of noise and airborne dust in the work area, we presented this data to the prevention company as it was certified and verified. Based on this, the standard of wearing helmets and earplugs was imposed throughout the factory, the number of areas where it is mandatory to wear a mask was increased and the mask was replaced by a more protective one” Pedro Cava, I+D & Marketing department at Lisanplast

This technology allows demonstrating the reliability of the data provided by the HOPU devices, detecting anomalies in the data. In addition, this process checks and certifies that the data conforms to the most demanding regulations.

This deployment has used the device calibration laboratory that HOPU has at its offices in Murcia, an environment with equipment certified by reference companies such as Envira, in relation to the supply and maintenance of laboratory equipment and Linde, in terms of the reference gases used. This laboratory also has ENAC certification, issued by SGS, which empowers HOPU to issue Calibration and Data Quality Certificates (CQC) for IoT devices. Through these CQCs based on the Besu B network (Blockchain), an intelligent contract is generated, stored in the device itself, which links the calibration process carried out in the laboratory, certifying that it has been verified and calibrated by a suitable laboratory.

“The use of Blockchain brings to our product a great differential innovation for the market, both for the Industry 4.0 and for a Smart City. This has been thanks to the support of Blockchers for the validation and to the Alastria Foundation of which we are partners” Germán Molina, CIO at HOPU

Once installed in the final environment, the device begins to collect data from the work area, detecting any high levels of harmful gases, suspended particles, odors, and noise, which may be harmful to the worker. Any anomaly or alert is stored in this device along with the time and date in a certified manner, ensuring that this data has not been altered. In this way, they can be exported by the occupational risk managers of this workspace or by regulatory companies associated with the company.